温室効果ガスおよびエネルギー管理

温室効果ガスおよびエネルギー管理

In accordance with international standard ISO 14064, SMIC establishes a greenhouse gas verification mechanism. It calculates the greenhouse gas emissions in the operating factory on a regular basis each year, to acquire the company's greenhouse gas emissions and implement emission reduction measures as planned.

At the beginning of 2014, SMIC set up Energy Conservation Committee to promote power management, where the Co-CEO served as Chairman of the Energy Conservation Committee and took overall charge of energy-saving related work. Besides, a sound energy management system was established to implement three-level energy management networks, practice the energy management post responsibility system, establish full-time energy management agencies and full-time managers for energy management, to ensure the implementation of energy management in both system and organizational construction. SMIC implemented energy-saving and emission reduction projects to achieve a double win for economic and environmental benefits.

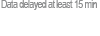

- Electric Energy Consumption Intensity

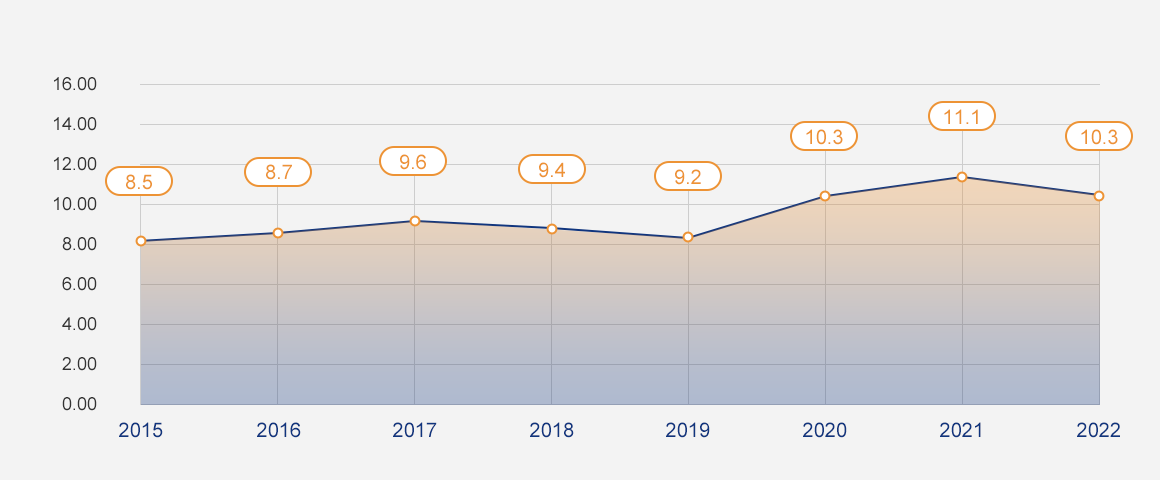

- Steam Consumption Intensity

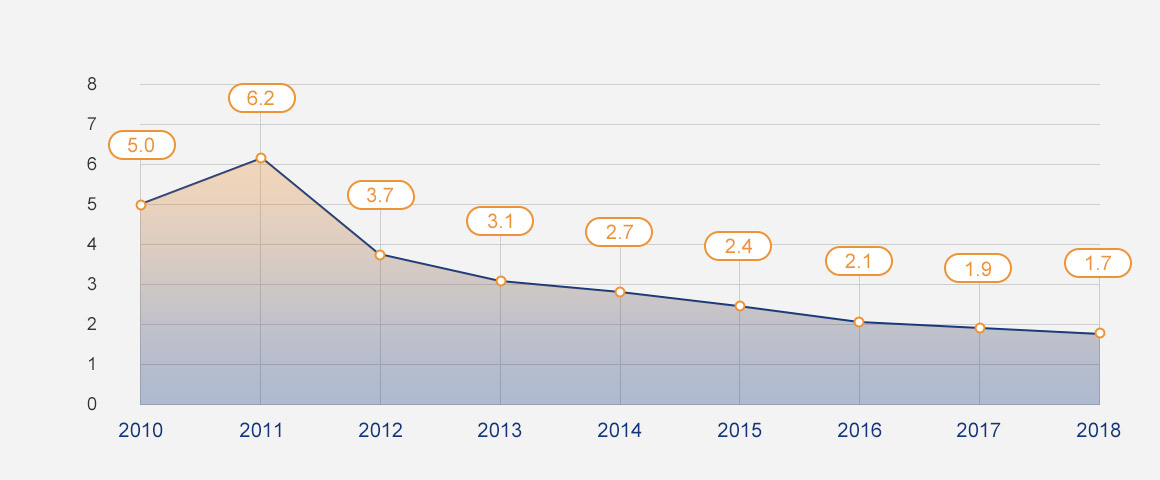

- Natural Gas Consumption Intensity

Electric Energy Consumption Intensity of SMIC (Unit:Unit: KWH/8’ equivalent wafer layer)

Steam Consumption Intensity of SMIC (Unit:Unit: KG/8’ equivalent wafer layer)

Natural Gas Consumption Intensity of SMIC (Unit:Unit: Liter /8’ equal wafer layer)

Other Pages Of Care for Environment

Other Pages Of Corporate Social Responsibility